In the fields of high-temperature material performance research and phase transition mechanism analysis, traditional external heating methods often fail to combine precise micro-region temperature control with real-time observation.

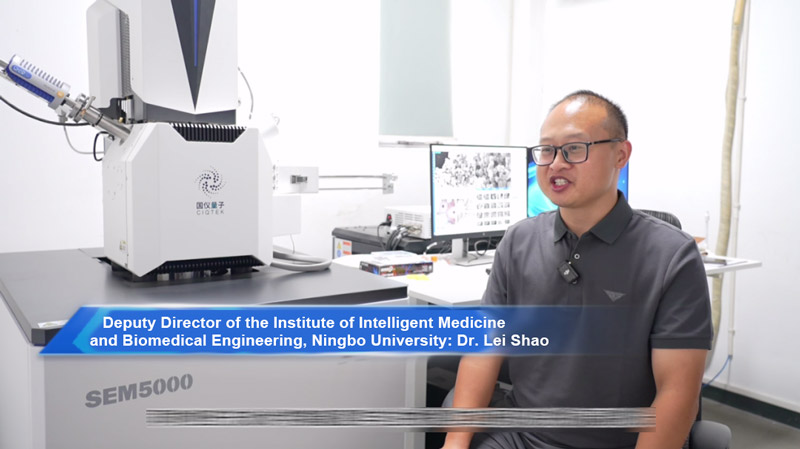

CIQTEK, in collaboration with the Micro-Nano Center of the University of Science and Technology of China, has developed an innovative in-situ heating chip solution. By integrating MEMS heating chips with dual-beam electron microscopes, this solution enables precise temperature control (from room temperature to 1100°C) and micro-dynamic analysis of samples, offering a new tool for studying material behavior in high-temperature environments.

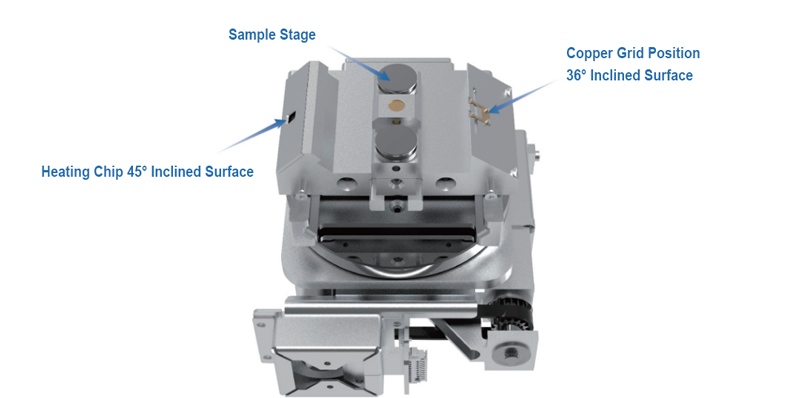

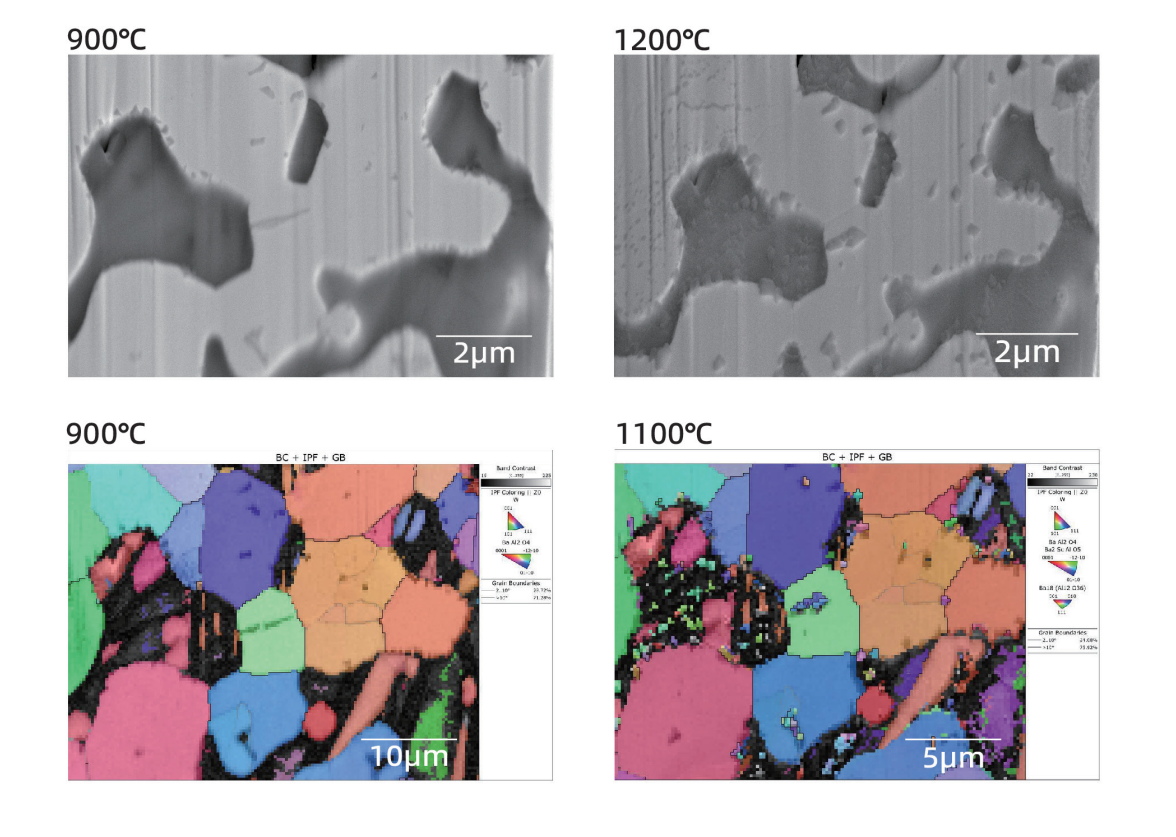

This solution uses the CIQTEK dual-beam SEM and specialized MEMS heating chips, with temperature control accuracy better than 0.1°C and temperature resolution better than 0.1°C. The system also features excellent temperature uniformity and low infrared radiation, ensuring stable analysis at high temperatures. The system supports various characterization techniques during heating, including micro-region morphology observation, EBSD crystal orientation analysis, and EDS composition analysis. This allows for a comprehensive understanding of phase transitions, stress evolution, and composition migration under thermal effects.

The system operates without breaking the vacuum, fulfilling the full process requirements for sample preparation and characterization (in-situ micro-region EBSD).

The integrated workflow design covers the entire process, from sample preparation (ion beam processing, nano-manipulator extraction) to in-situ welding and heating tests. The system supports multi-angle operation, featuring a 45° heating chip and a 36° copper grid position, which meet the complex experimental needs. The system has been successfully applied in high-temperature performance research of alloys, ceramics, and semiconductors, helping users gain deeper insights into material responses in real-world environments.

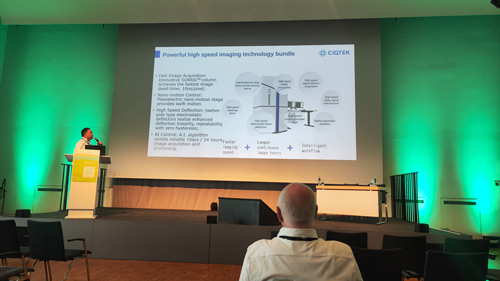

September 26–30, Wuhan | 2025 Chinese National Conference on Electron Microscopy

CIQTEK's eight major electron microscopy solutions will be showcased!